The raw potential of new technology is astonishing, from IoT, to blockchains, data lakes, and AI. Although it is getting easier to use many of these, it is incredibly difficult to understand how any particular technology leads to transformational opportunities. In particular, it is difficult to adapt the technology to the unique needs of the organisation and to integrate it with current processes.

To further complicate matters, most enterprises have ingrained legacy systems that are difficult to modify. One can only solve these problems with individuals with technical depth, scope, and the ability to work hand-in-hand with the wider organisation.

The reality is that in many industries today, most data is not up to basic standards, and the rigours of change require far better data quality and analytics.

Data poses a fascinating paradox; transformation involves understanding emerging types of unstructured data, huge quantities of data external to the business, leveraging and incorporating proprietary data, all while shedding massive amounts of information that has never been (and will never be) used.

THE BUSINESS CASE

Today technology can help by allowing businesses to capture data on Environment, Health & Safety, it’s not just about incidents. Leading indicators against a predefined set of requirements, using intuitive online and offline protocols, are already as important as the lagging indicators. This helps to collate information in a predefined manner that is compliant and importantly, drives continual EHS improvement and culture change.

Once the data is obtained, it is important to act on it. Technology enables businesses to respond to such cases within predefined parameters to a satisfactory close. Furthermore, comprehensive EHS and compliance software systems provide organisations with a central location for consistent logging of events, assigning corrective measures, analysing root causes and reporting on incident rates.

Many organisations are leveraging the use of dedicated and integrated iOS and Android incident management mobile apps to enhance EHS management and reporting by allowing employees to record findings or incident reports on the go. Apps can also have offline support in case the user is not online; tasks and activities can be inserted and completed on the move, and information synchronised to the cloud at a later stage.

A CASE STUDY

Sandvik has over 43,000 employees across the globe. Sandvik Mining and Rock Solutions (SMR) division has eight product areas: rotary drilling, load and haul, mechanical cutting, parts and services, rock tools, rock drills and technologies, surface drilling and exploration, and underground drilling.

Sandvik has over 43,000 employees across the globe. Sandvik Mining and Rock Solutions (SMR) division has eight product areas: rotary drilling, load and haul, mechanical cutting, parts and services, rock tools, rock drills and technologies, surface drilling and exploration, and underground drilling.

We now look at how Sandvik Mining and Rock Solutions innovated its entire approach with Culture-Changing EHS Reporting.

THE CHALLANGES

In 2006, SMR introduced EHS reporting using spreadsheets for the capture and communication of EHS data.

Over time, the reporting needs of SMR have become more complicated. SMR’s EHS goal is to continually improve both its EHS culture and its management systems.

SMR recognised that it needed to use its reporting not only to track outcomes, but also to allow a wider, more holistic view of data to ensure greater transparency, promote good decision-making, and recognise key areas for change and investment.

In order to retain its market-leading position, SMR pursued a path that would allow it to assess behavioural change by reporting both quantitative and qualitative data.

With this strategy, the goal was to translate data into information to strengthen the value of EHS across the enterprise, to build and implement a culture of EHS awareness, and to enable staff to take ownership of EHS on an individual basis.

THE SOLUTION

SMR opted to go with SAI Global’s SAI360 platform and has achieved what it aims to do: significantly improve it’s EHS performance by simultaneously improving both the management systems and the EHS culture.

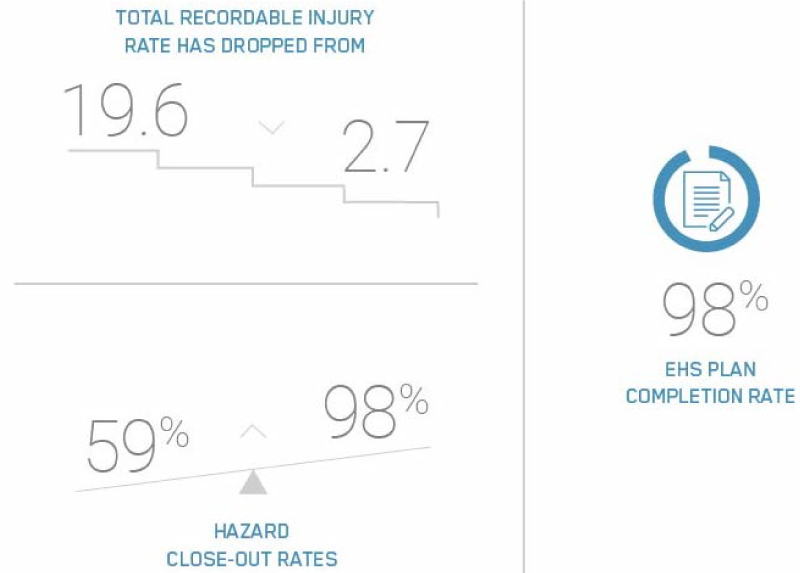

The numbers support this belief – 88% of employees rated the EHS culture as strong or very strong in their last employee survey. Looking at the lagging safety indicators, in the years after the solution was implemented, the Total Recordable Injury Frequency Rate fell from 19.6 to 2.7 at the end of February 2021 and the Lost Time Injury Frequency Rate is now at 0.67.

But that’s not all; with greater openness and a common sense of the importance of EHS success, the atmosphere is different, and workers take on individual ownership and accountability.

SMR has also used SAI360 for EHS to generate EHS League Tables, which places a focus on several Leading Indicators of EHS performance in areas where it was identified that some behavioural change was needed.

• Close-out rates have risen from 59% to a consistent 98%, whereas the number of hazards identified due to a significantly improved safety culture has increased by 200% over the same era.

• The annual site-based completion rate of the EHS plan is now is above 98% for all sites. Before, they had not been finished in time or had been completed by the end of the year.

• Reporting Performance (within allocated time-frames) has improved with the average monthly score increasing from 9.2 (of possible 20) in 2015 to 16.5 in 2020 – this is an 80% increase in performance.

• Every location has established a Health & Wellbeing Program that has been developed in consultation with the workforce. The Health & Wellbeing programs are made up of approximately 362 separate elements for 2021 (an element is an individual topic within the program) under the classification of either physical, psychosocial, social, economic, spiritual and personal development. These programs are declared, monitored and progressed in a systematic manner using the platform’s functionality.

CONCLUSION – PACKING IT ALL UP

There is far more to consider than the financial bottom line in today’s cut-throat business world. As well as generating revenue, companies must be able to demonstrate to all of its stakeholders (e.g. investors, customers, regulators, local communities) that it has the capability to meet all expectations associated with having a “social license to operate”.

Collecting, managing, reporting and analysing data is a vital part of every EHS Management System. Human error will never go away, and there will always be an inherent risk of failures in equipment and procedures. That said, a comprehensive and efficient data management system will arguably be one of the most important ways to develop prevention strategies.

To address all these challenges, many companies are searching for digital technologies that enable them to evolve from manual spread sheet-based processes to a fully integrated EHS solution expanding their capabilities.

As highlighted in Sandvik’s case above, technologies such as the one from SAI Global can help EHS experts significantly improve worker safety and incident management by optimising the system to change the culture.

Furthermore, with greater transparency and a shared understanding of the value of EHS performance, a local EHS culture will improve by supporting individuals in taking greater ownership and accountability for the risks and controls in their workplace.

ABOUT SAI GLOBAL

SAI Global helps risk and compliance professionals proactively manage risk to create trust and achieve business excellence, growth and sustainability for their organizations.

SAI Global helps risk and compliance professionals proactively manage risk to create trust and achieve business excellence, growth and sustainability for their organizations.

SAI360, our world-leading Risk platform, is the most complete integrated approach to risk management on the market including compliance management, enterprise & operational risk management, EHS & operational excellence, ethics & compliance learning and digital risk & business continuity use cases. Combining market-leading software capabilities, learning content and

controls, SAI360 provides a line of sight to navigate risk and compliance management by addressing it from every perspective.

SAI Global is headquartered in Chicago, U.S., and operates across Europe, the Middle East, Africa, the Americas, Asia and the Pacific. Discover more on our website or follow us on LinkedIn. To see SAI360 in action, request a demo.